Summary

AI warehouse automation is taking flight with RPA. It’s more than just moving things; it solves all bottlenecks. Moving from simply stacking to auto packing and delivering it handles everything. Automated warehouse system management powered with RPA and AI can handle end-to-end operations with efficiency and accuracy. This is a game-changing move that is already in the industry, and early birds are already cashing out fairly well with it. If you want to be in the race too, and dive ahead, check this blog; it gives you all the details you need to know about automated WMS.

Warehouse tasks are completed. Imagine receiving this message while you are sleeping. Welcome to the era of the Autonomous warehouse management system powered by AI and RPA.

You still get curious about how it is possible. You go back to the checklist and check whether every task and every detail is met. To your surprise, it is all done. Because this is not your traditional warehouse system, it is an auto-pilot run warehouse that works for mid-size logistics, small businesses, and enterprises, too.

If this piqued your curiosity, we are sure the blog will leave you stunned and with plenty of information, ready to autopilot your tasks. Not by hiring more staff, not by working overtime, not by reducing your process, but just by integrating small and churning huge ROIs.

What is the Automated Warehouse Management System?

A mid-sized 3PL in Texas implemented AI-powered automation in its 137,000 square-foot warehouse. Within 90 days, they cut order processing from 6.2 hours to 47 minutes. Their accuracy jumped from 94.7% to 99.4%. The unexpected win? They stopped hiring seasonal workers entirely because their system predicted demand spikes 2 weeks out and automatically adjusted workflows.

That’s not a vendor’s pitch deck. That’s live data from GXO’s 2024 implementation with Ocado’s robotic systems.

So it’s another AI to replace humans. Well NO! It’s a smarter tool for collaborating humans and machines to reduce manual, monotonous tasks, reduce errors, and grow your business. It’s not about replacing people. It’s upgrading from manual to a more automated and faster version.

Warehouse management systems act as the brain that manages inventory, orders, and workflow. At the same time, AI that’s smart enough to handle tasks and use its power to predict things adds an extra layer of intelligence. How? Instead of executing things in circles, AI learns, predicts, and makes recommendations. With the RPA combination, it executes tasks and implements decisions automatically.

Now you might feel the risk. But no, this works in a human loop. And data training and feeding are equally important to run all these systems.

‘What if I don’t have data? ’ To your answer, all businesses have data, offline or online. All they need is data engineering services to make things possible and rightly aligned.

By combining these hi-tech and AI Integration, warehouses are now running operations intelligently, and the team has one extra task: monitoring them, training them (must be done periodically), and resolving issues.

So in simple terms, Automated Warehouse management systems focus on:

- Tracks inventory: It knows exactly what products are in the warehouse and where they’re located.

- Manages orders: When someone places an order, the WMS helps select the right products, pack them, and ship them.

- Improves efficiency: It helps workers do their jobs faster and more accurately by providing clear instructions on where to find things and what to do next.

What Problems Are You Actually Solving With an Automated Warehouse Management System?

Use of AI in warehouse management is no bluff story. It’s realistic. They transform every aspect and bring efficiency, control, and peace of mind.

Scenario 1 – “Sudden Order Spike Demands”

You were not prepared for a spike in orders. Suddenly, now you have business. But you are running out of stock or have limited stock in the warehouse. You ask a worker to do the manual counting, and meanwhile, you run for emergency shipments setup and all. Suddenly, a barcode scanner fails, and you have all things loaded on a plate. Now what? You have to manage things manually. Hire an extra resource. Work overtime.

But let’s solve all this with an automated warehouse management system.

Scenario 2 – (with an automated warehouse management system)

“The Multi-Location Inventory Mystery”

You have three warehouses. A customer orders five items. Your team checks location A: 2 items available. Location B – one item. Location C – has all five, but it’s the furthest from the customer.

Without automation, someone has to make a judgment call. They could split-ship, doubling your freight costs. Maybe they ship from a distant warehouse, missing your delivery promise. They could spend 20 minutes checking stock levels across systems that don’t talk to each other.

With an automated WMS? The system checks all locations in milliseconds, calculates shipping costs, considers delivery promises, and routes the order optimally. Done before your warehouse manager even sees it.

Now you must be stunned with a “Wow” reaction. Well, that’s what an automated warehouse management system is all about.

Curious to know and build a warehouse management system for your business? But I still want to know more use cases and scenarios. Pick our 2 Hour FREE consultation. It won’t cost you a dime. But you will surely get expert opinions that provide a 360-degree view of the automated warehouse management system.

Drive Clarity With Strategic Insights, Get 2 Hours of Free Consultation.

Book Now!

Why AI Integration Matters in Warehouse Automation?

What is the idea if you have just papers? Though you build with the smartest AI model, you can’t communicate with the inventory system, what’s the use of it?

That is where Hidden Brains experts come in. Your entire system will speak a universal language, no matter where they are located and how, with the right integration and end-to-end development. We help you build a solution that integrates with your inventory system, collaborates with your ERP, connects with your transportation management system, and updates with shipping platforms. This is not just a dashboard; it’s a huge SYSTEM that runs to understand your business, process, and operations. This is what you wanted, right?

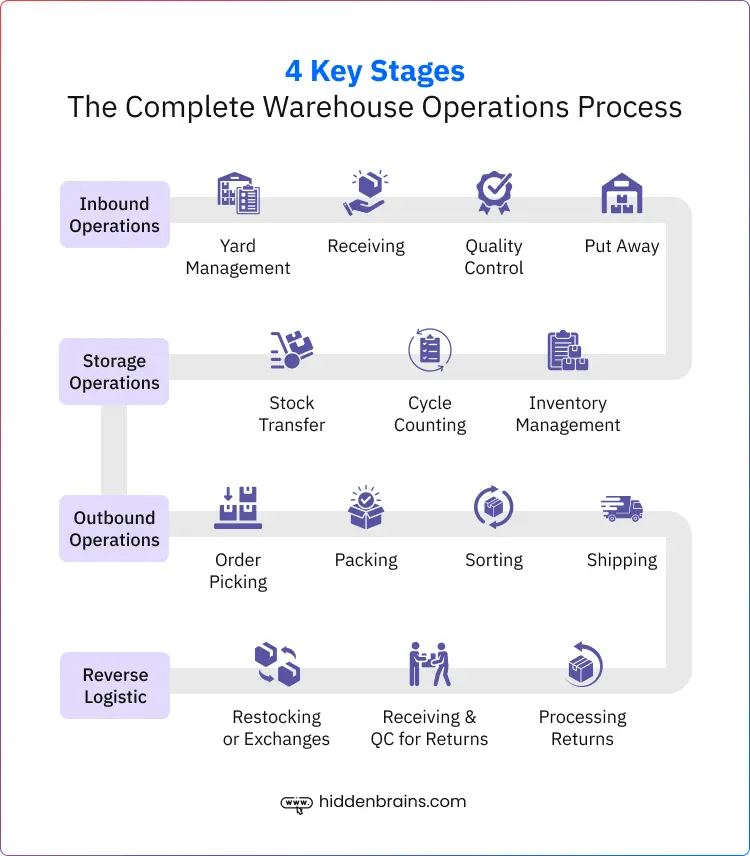

What Does a Real Automation Warehouse Management System Cover?

Think of it as an umbrella that connects all the layers:

- Inventory Management: Your AI seamlessly integrates with your inventory system, predicting demand and automating restocking and replenishment processes. No more stockouts or overstocking, just accurate, real-time inventory.

- ERP Collaboration: Your AI system communicates with your ERP system, keeping your warehouse processes in sync with financial data, order management, and business performance metrics. You get a single source of truth that drives smarter business decisions.

- Transportation Management: From the moment an order is processed until it reaches the customer, your transportation management system is seamlessly connected to your AI warehouse. Optimize routes, delivery schedules, and fuel costs, all while improving delivery times.

- Shipping Platforms: Your warehouse system seamlessly integrates with your shipping platforms, ensuring real-time, accurate updates. Orders are shipped faster, mistakes are minimized, and your customers get exactly what they want when they want it.

Cut Processing Time & Optimize Workflow for Better ROI.

Start ScalingLet’s Help You Out With the Complete Flow of the Automated Warehouse Management System

Order placed → WMS receives via API → AI checks inventory across locations → Assigns pick task → RPA updates ERP → Vision system verifies items → Packing gets box size recommendation → Best carrier selected → Tracking updates customer → Inventory adjusts everywhere → Reorder triggered if needed → System learns for next time.

Do you find this easy? Well, we do too. You must have seen a few giants already dominating the industry and their secret sauce, which is no more secret: that’s an automated inventory management system.

Now What Success Actually Looks Like (Time for Some Real Numbers)

No, this is not a gimmick number. These are really realistic success metrics.

Month 1-3: Foundation Building

- 15-20% reduction in manual data entry.

- System recommendations achieve a 75% acceptance rate (your team is learning to trust it)

- Error rates improve 10-15%

- You catch your first major benefit: a stockout that would have happened is prevented because AI predicted a demand spike.

Month 4-6: Momentum Phase

- Order accuracy improves to 99%+ (from typical 94-96%)

- Peak season doesn’t require temp hiring because AI-optimized staffing is two weeks early.

- Pick rates increase 25-40% with AMR assistance.

- Returns processing time drops 50%

Month 7-12: Autonomous Operation

GXO implemented warehouse automation across its retail operations, and the technology uses machine learning to double productivity and improve accuracy by as much as 40% compared to manual methods.

Ocado’s fully automated fulfillment centers can process up to 65,000 orders per week, with each order averaging 50 items. Their robots move across a three-dimensional grid at 4 meters per second, with an air traffic control system managing hundreds of them simultaneously. Orders can be processed and ready for dispatch in as little as five minutes.

Year 2+: Compound Benefits You’re running 30% more volume with the exact headcount. But the real wins are subtler:

- Your WMS automatically adjusts slotting based on changes in velocity.

- AI predicts equipment maintenance needs before failures occur.

- Your team solves interesting problems instead of fighting daily fires.

- Customer satisfaction improves because promises are kept.

Streamline Fulfillment Now With Advanced Ecommerce Tech.

Get Started!

Cost Conversation With Automated Warehouse Management System

Now, let’s talk about numbers that are cashing in.

Initial Investment Ranges (for 100,000-200,000 sq ft facility):

- Basic RPA implementation: $40K-$80K

- Mid-tier AI + RPA + AMR integration: $150K-$400K

- Advanced end-to-end automation: $500K-$2M+

But that’s just software and hardware. Integration costs often run 30-40% of total spend. If you’re quoted $300K for tech, budget another $120K for integration, training, and first-year support.

The ROI reality: The average ROI for these implementations is estimated at 20% within the first two years.

Better numbers from the field: warehouses implementing automation see payback in 14-22 months through:

- Labor optimization: 25-30% reduction in repetitive task hours

- Accuracy improvements: 35-40% reduction in shipping errors and returns

- Throughput gains: 40-60% increase in orders per day with the same staff

- Space utilization: 20-30% better cube utilization through intelligent slotting

Where AI and RPA in WMS Go Next?

We are not just building an automated warehouse to fix things for now. Or just to dump for more automation. We are laying the groundwork for the upcoming era of intelligent, interconnected systems that shape the future of the supply chain.

- Predictive Smart Supply Chains

Imagine a world where your warehouse doesn’t react to orders, but anticipates them. By analyzing customer behaviour, social media trends, weather patterns, and economic trends, we forecast and position inventory long before it’s needed. The result? No more surprises. Just predictive demand fulfillment. - Autonomous, End-to-End Delivery Networks

Order received, robots pack it and hand it off to the delivery. Yes, this is the future of last-mile integration. While AI helps at every step from warehouse to doorstep, you build trust and relationships and give them experience, all while cutting costs. - Dynamic Data-Driven Pricing Models

A warehouse can suggest to you to offer promotions or discounts, and that also in real-time? Yes! During off-peak periods, automated pricing algorithms adjust to sell slow-moving inventory profitably, aligning your pricing with fulfillment capacity to optimize both customer satisfaction and margins.

Your Next Move

Consult. Strategize. Build.

We are your true partners. We know behind the scenes and questions. To balance out both side stories, we have a win-win for you.

You don’t need an entire overhaul of the operation at once. You can start with one workflow, one pain point, and one measurable outcome. Start with one pain point, solve it, get a measurable outcome, and then plan. That’s starting with baselines and turning to automation.

Measure ruthlessly. Get real value. Then expand.

Whether it’s for radical expansion or starting in modules, we are there for you. Our customized, right-fit warehouse management system services can help you get the most out of it. Contact Us or email us. We are there for you.

Frequently Asked Questions

Did we miss something in our blog? Check out a few FAQs that got all covered.

What is an automated warehouse?

An automated warehouse uses AI, robotics, and automated systems to streamline operations, enhancing efficiency, speed, and accuracy while reducing human intervention.

What are the three levels of warehouse automation?

1. Basic Automation: Simple tasks like barcode scanning and conveyor systems.

2. Partial Automation: Involves AI-driven systems for tasks like picking and sorting.

3. Full Automation: Complete automation, including robots, AI, and RPA integrated with the WMS for end-to-end operations.

How does AI improve warehouse efficiency and accuracy?

AI enhances efficiency by predicting demand, optimizing inventory management, and automating decision-making, leading to faster processing and fewer errors.

What are the main benefits of using AI in warehouse management?

AI boosts productivity, reduces costs, enhances accuracy, improves inventory control, and enables faster order fulfillment, all while optimizing the supply chain.

How is RPA used in warehouse automation?

RPA automates repetitive tasks like data entry, order processing, and inventory tracking, enabling faster, error-free operations with minimal human intervention.

What is the difference between AI and RPA in warehouse operations?

AI focuses on decision-making and optimization, using data to predict and improve processes, while RPA automates repetitive, rule-based tasks for efficiency.

How do AI and RPA integrate with a modern WMS?

AI and RPA seamlessly integrate with WMSs, optimizing decision-making, automating workflows, and providing real-time data to improve control and efficiency in warehouse operations.

What are the most common use cases of AI in warehouses today?

AI is used for inventory management, demand forecasting, robotic picking, route optimization, and real-time tracking to ensure smarter, more efficient operations.

How much does it cost to implement AI warehouse automation?

Costs vary widely depending on scale and complexity, but on average, small to mid-sized AI warehouse automation systems start around $80K-$400K, with larger systems reaching into the millions.

Conclusion

Automation is not just the present; it’s the future, and it’s already ahead. But none of this progress is possible without solid integration and strategic planning. The foundation of automated warehouses is critical to unlocking these next-generation capabilities, and the time to build it is now.

This technology isn’t a passing trend; it’s here to stay. The sooner you start, the greater your chances of leading the charge. While others are still playing catch-up, you’ll be busy polishing, upgrading, and continually creating more advanced versions of success, ensuring your position as an industry leader.

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg)

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg?1.0.0)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg?1.0.0)