Quick Summary:

Why is predictive analytics in supply chain control towers with AI regaining momentum and beating the competition at a fast pace? The answer is simple: AI empowers control towers to not just report but predict and prescribe, enabling businesses to make proactive decisions, reduce costs, and optimize their operations in real-time. Check out the insights and a clear guide on how to move with a predictive supply chain control tower with AI.

You thought your holistic dashboard gave you control, letting you see orders, inventory, and logistics in one place. But the majority of supply chain leaders say their visibility tools still can’t predict disruptions.

While you’re watching last week’s data, billions in supply chain value evaporate each year due to poor forecasting. Your dashboard is telling you the truth, but it’s not telling you about the loopholes. It doesn’t define what could happen next. This is where your competitors got an advantage. They turned on predictive analytics in the supply chain and forecasted way before they happened.

Once you thought ‘control house’ actually failed because it was just to show the insights, not to act on lurking missed opportunities or possibilities of how you can make things better. Powered with an AI predictive supply chain control tower, it is your “intelligent decision-making engine” that moves from monitoring to recommendation and automation.

Of course, all these things are not innate; they are trained and refined by humans, often with support from an AI Chatbot Development Company, combining their expertise with the power of AI. This creates a truly responsive, proactive, and smarter supply chain.

Now, before we dive into the ins and outs of predictive supply chain control towers with AI, let’s check a few insights on how it’s impacting all areas.

A Quick Summary of What’s Happening Around in Industry and Predictive Analytics Adoption Rate.

| Industry/Segment | Predictive Analytics Adoption Rate | Key Use Cases in Supply Chain |

|---|---|---|

| Third-Party Logistics (3PLs) | 80% | Demand forecasting, inventory optimization, and route planning |

| Shippers | 77% | Inventory management, shipment tracking, risk mitigation |

| Manufacturing | 53–55% | Production planning, quality control, supplier risk management |

| Retail | 53–65% | Demand forecasting, inventory optimization, and customer service |

| Healthcare | 57% | Inventory management, demand forecasting, risk mitigation |

| Logistics & Transportation | 46–53% | Route optimization, fleet management, and delivery scheduling |

| Sustainability | 62% | Carbon tracking, responsible sourcing, compliance |

What is the Dire Need of a Predictive Supply Chain Control Tower?

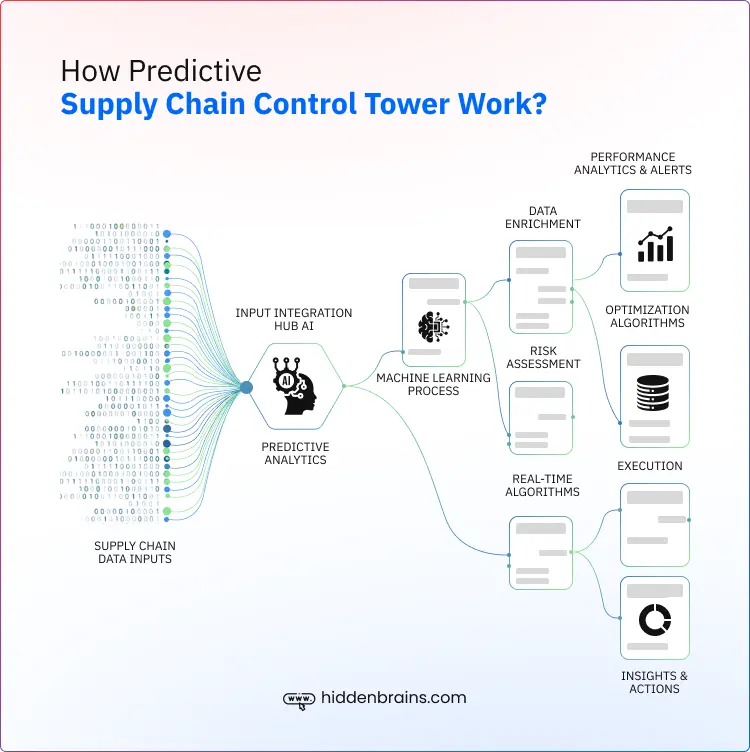

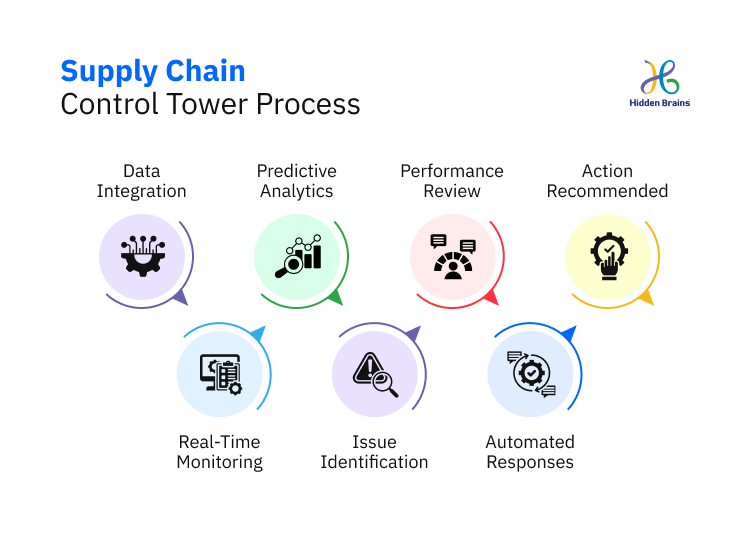

In layman’s terms, a predictive supply chain control tower is a centralized platform that fetches data from multiple sources – suppliers, manufacturers, distributors, and logistics providers on a single portal.

Before you move ahead, you need to understand how AI in logistics is bringing a real revolution in this era.

Supply Chain: This is the entire journey your product takes, from raw materials to the customer’s hands.

(suppliers → warehouse → truck → store)

Predictive Control Tower: Your supply chain’s GPS + crystal ball + autopilot, all in one. It doesn’t just show you where things are. It predicts where problems will happen and fixes them before you even notice.

Understand with this example;

Scenario – Disruption Forecasting BEFORE It Happens

Traditional: “Port congestion detected!”

Predictive: “Based on weather patterns, labor negotiations, and historical data, the Port of LA will likely experience a 40% congestion increase in 72 hours. Alternative routes calculated. Carrier negotiations initiated.”

The difference? Three days of lead time to act, rather than three days of detention fees.

Modern AI-powered predictive supply chain towers have evolved into autonomous command centers that can predict disruptions, help you reroute, and manage the supply chain in real time so that your business and time-critical clients don’t have to suffer.

Let’s go with one more scenario for better understanding.

Multi-tier Visibility Beyond the First Layer

In simple terms, the supply chain isn’t about just one tier. It’s a multi-tier and multi-channel partner cycle. And here is just a glimpse of the problem in this multi-tier loop.

Tier 1 = Your direct suppliers (the people you call when you need stuff)

Tier 2 = Your suppliers’ suppliers (the people THEY call)

Tier 3 = You get the idea… it goes deep.

Most companies can only see Tier 1. Predictive towers see ALL the layers. So when a chip factory in Taiwan has a fire, you know IMMEDIATELY which of YOUR products are affected before your Tier 1 supplier even realizes there’s a problem.

Breaking the visibility barrier beyond Tier 1 enables organizations to look across their extended supply chain, identify new risks deeper in the supply chain, and drive ESG goals through improved traceability.

Remember Nike’s $100 million supply chain disaster in 2000? A software glitch in their demand planning system led to inventory mismatches, resulting in over $100 million in lost sales and a 20% drop in stock price.

The problem? They couldn’t see beyond their immediate suppliers.

Don’t like these hidden losses sneak up on you.

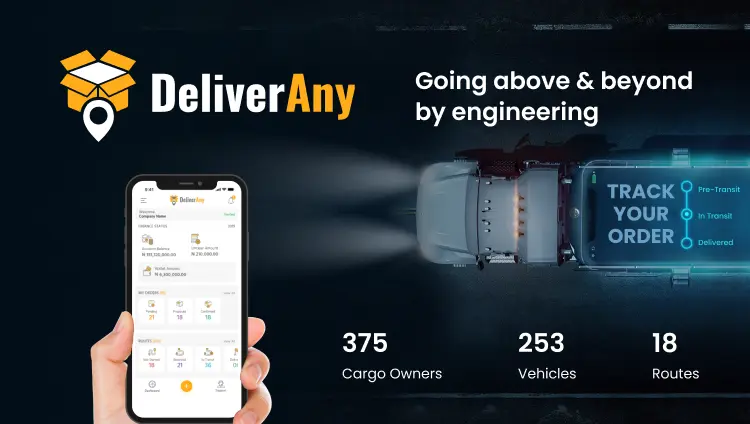

Just like we helped DeliverAny unlock the true potential of their operations, we can help you see the bigger picture too—more business, smoother processes, and growth into new markets. You could start small, too, with a 2-Hour Free Consultation with experts to get all your queries solved and move proactively to the next business opportunity.

Traditional control towers have turned into a “more people, not less” solution. However, the mantra was to reduce work on people and move towards better predictivity. You have now hired data analysts to interpret data. Then, more experts to reconcile conflicting data. Adding one more layer of a project manager to coordinate with everyone and analyse.

Now, you have that picture of what started as a cost-saving investment has become a non-stop loop of hiring more to solve the problem.

And what’s more wounding is that this risks reputational damage, compliance violations, and even multi-million-dollar losses. It takes your customer a minute to turn to your competitor. Procrastination could risk your business and profits.

The 3 Pillars – What Makes Predictive Towers Actually Work?

The secret sauce behind AI-powered predictive towers in the supply chain actually works because strong approaches back them.

I. Predictive Analytics That Can Actually Forecast

Predictive analysis in the supply chain goes beyond just the static records. They are a combination of psychologist and strategist who examine past patterns to predict future events. This could be weather patterns, demand fluctuations, or even geopolitical shifts. We know this is a real advantage. And this is what you have been missing out on to escalate your business.

II. Prescriptive Action Engines

You know the symptoms. But you actually need a doctor to prescribe your medicines. This is where prescriptive analytics in the supply chain comes into action. These prescriptive action engines suggest the best course of action, like rerouting shipments, adjusting inventory levels, or triggering automated procurement, and more. Prescriptive actions streamline the decision-making process, making the supply chain more responsive, agile, and ready to respond effectively.

III. Digital Twin Simulation

In your experience, you must have faced unexpected issues in real time. And this is something you can’t even think of. But a Digital twin is smart enough to predict all these “what-if” scenarios without overlooking real-world operations. It gives a business an advantage by allowing it to test different strategies, understand the deep impact of certain actions, and make data-driven decisions accordingly.

Testing “what-if” scenarios and being prepared adds an extra layer of confidence and decision-making power. Isn’t it a real gold where your business gets risk-free ground for testing scenarios?

The New Economies With Predictive Analytics in Supply Chain

We know that business thrives on cash in and cash out. The entire story is based on it. Here, we showcase new numbers that are actually achievable with AI-powered supply chain control towers.

Payback Period

Most of the AI-powered control tower organizations have achieved payback within a YEAR. Where average disruptions took 34 manual system updates across 6 platforms, they have cut this to one.

ROI Framework For Your Business With Predictive Analytics in Supply Chain

Operational Saving for Enterprise

- 30-40% reduction in detention and demurrage costs.

- 6-10x savings on expedited freight by avoiding last-minute scrambles.

- Route optimization cuts freight spend by 15-20%.

- In automotive, avoiding even one 4-hour line stoppage can pay for an entire quarter’s control tower investment.

Productivity Gains

- Eliminate 60-70% of manual data reconciliation time.

- Scale operations without adding headcount.

- Free your supply chain team from firefighting to strategic work.

Revenue Protection and Growth

- 20-30% increase in NPS (net promoter score) marks better service reliability.

- Service differentiation in commoditized markets (premium pricing).

- Faster time-to-market: 9-12 month product cycles are reduced to half.

Real Talk – Case Studies With Predictive Supply Chain

- Walmart – Turned to real-time tracking, on-time delivery performance, inventory optimization, cost reduction, and more. Their RFID mandate for suppliers in 2024 operates the largest private motor carrier fleet in North America. What changed all this? They could predict. They redirected trucks mid-route based on real-time demand signals.

- DHL – Predictive system led to a 15% improvement in delivery time accuracy and a significant reduction in operational costs. Their genius move using predictive analytics gave them the advantage of being a revenue generator, not just a cost center.

- DeliverAny – Powered by Hidden Brains, Delivery Any is a bespoke logistics service platform for cargo owners and logistics service companies. It’s a predictive, consistent, effective, innovative, and future-ready shipping & logistics solution that helped cut transportation costs and gain visibility & transparency into the complex supply chain process.

Let’s make it happen! It brings predictive analytics to your supply chain.

How to Build a Predictive Analytics Strategy: A Beginner’s Blueprint

Alright, now all-in. Now comes the hard part. How to build the right blueprint and get more of it.

Our 22+ years of experience can guide you through this.

Step 1 – Assess Your Data

Before you dive in, assess your data maturity. Is your data messy? Will AI just automate or create more chaos? Make this nasty work first. Or get data engineering services to make this happen.

Step 2 – Audit Your Existing Tech Stack

Your ERP, WMS, and TMS actually talk to each other? Or are they just speaking their own language? It’s about ensuring smooth, efficient, and scalable operations. If these are not possible, it can lead to analysis paralysis.

Step 3 – Get a Partner

Get a partner who has strong experience that is actually visible beyond PowerPoint. You need a Hidden Brains partner who can keep pace with your business. We have a strong portfolio in supply chain solutions that help you throughout the journey.

Step 4 – Define Success Metrics

Set clear metrics. Define your goals and requirements.

Is it inventory?

Is it ERP?

On-time delivery?

Freight cost reduction?

Or just upgrading?

Pick 3-5 KPIs and make them non-negotiable.

Some Insights No One Will Tell You:

- The secret sauce is not giving your people the treatment of “AI will replace you,” but instead making them partners, because they know the system, processes, and business better. Their experience and strategic moves in AI will help you outdo the competition.

- If your data is not clean, there’s a high chance you won’t get results within that timeframe.

- Train your team to use ‘Predictive analytics supply chain powered by AI’, else there is no reason to invest. And your ROI will go straight to zero.

- AI models are more about training and improving. Get frequent maintenance and upgrades to help you thrive and churn more results.

Your Move Matters For Your Business

To be honest, Tier 1 and Tier 2 manufacturers are facing nearly 90% more supply interruptions than in 2020, and recovery times have stretched by more than a month on average.

62% of respondents perceive global supply chain risks as “high” or “very high,” with 68% anticipating further escalation in 2025. Your competitors aren’t waiting for the perfect moment. They’re moving NOW.

It leaves you with three choices.

- Ignore (stick with dashboard)

- Pilot (start with modules and then expand)

- Transform (the bold enterprise-wide deployment)

It’s time to move beyond the dashboard. Take advantage of Predictive control towers with AI and make more wins for your business—partner with Hidden Brains. Our expertise and strong market foothold give you the advantage of developing the best solution. It’s time to dive into a multi-billion-dollar opportunity ahead with our software development company.

Frequently Asked Questions

What is an AI-powered predictive supply chain control tower?

Consider an AI-powered predictive supply chain control tower as a centralized system to see all your air traffic. It acts as a controller to manage the entire process, from making to delivering products. The control tower brings in data from every part of the business in one place. This gives you the power of a single, clear view. With predictive, it can help you predict and prevent them, making the entire process cheaper, faster, and more reliable for customers.

How to architect a predictive supply chain control tower?

An AI-powered predictive supply chain control tower is a layered approach. It’s like building a house, step by step. The foundation layer is the data layer that’s crucial for operating it all. The cleaner the data, the better the chances of getting good results.

The second step is visibility and monitoring with a Digital twin. It’s like building a digital model of the entire supply chain that shows exactly where every shipment item is right now.

Third is adding a brain with machine learning algorithms. You feed, the better output results you will get.

Fourth is building a control deck where the human team takes action based on AI’s advice.

The process is comprehensive and long, but it surely gives results that matter.

What is the ROI of implementing AI in supply chain control towers?

Every dollar or penny you spend in the AI supply chain control towers can translate to more benefits. It can cut down 15% to 35% in inventory for logistics, it can reduce 5 to 20% while for planning and admin time, it can reduce 25% to 80%. Beyond this, you would receive the benefits of no missed sales, customer satisfaction, resilience, and more.

What’s the difference between predictive analytics vs. real-time dashboards in the supply chain?

In simple terms, it’s like ‘What’s happening now’ to predicting ‘what will happen next’. This is the difference between real-time dashboards to predictive analytics. Think of real-time dashboards like a speedometer, like how fast you are going. And predictive analytics is having a crystal ball in hand that warns you of traffic 50 miles ahead and suggests an entirely new route.

What is the Future of AI in supply chain optimization?

The future of AI is more than just predictions. It’s about autonomy, resilience, and sustainability. The supply chain is turning to be a doctor that self-treats and heals. AI in the supply chain will take every operational decision and will automatically improve at every step. This doesn’t mean human is out of context. But humans matter due to their critical thinking, decision-making insights, and vision.

What’s the biggest reason implementations fail?

Implementations fail due to poor adoption, misaligned processes, and data connectivity issues, not the technology itself. But before falling, it’s better to get a second opinion and consult, what are the odds and evens of it?

What’s the cost of implementing a predictive supply chain control tower?

The cost typically starts at $500K-$1M for smaller companies, with $3M-$10M+ for global operations, depending on the complexity and scale.

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg)

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg?1.0.0)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg?1.0.0)