Summary:

From drones inspecting tanks to AI predicting equipment failures, the oil and gas industry is rapidly going digital. Companies are ditching outdated systems and embracing powerful software solutions to boost efficiency, cut costs, and stay competitive. This blog explores how automation, cloud platforms, AI, and IoT are transforming field operations and boardroom decisions alike. Whether it’s smarter maintenance, remote access, or real-time insights, digital tools are rewriting how oil & gas enterprises work. If you’re in this space, it’s time to move forward, or risk falling behind.

Delek US Holdings, Inc. recently started using drones to inspect petroleum tanks and process units. But here’s the game-changer: those drones are powered by smart, custom-built oil & gas software.

That demonstrates how far the industry has progressed.

Just a decade ago, these things were unthinkable. Today, they’re becoming the norm. The oil & gas automation market is expected to reach $42.6 billion by 2033. That’s massive. Thanks to digitization, the number will only keep growing.

From field operations to boardroom decisions, digitization is rewriting the rules, enabling oil and gas enterprises to get rid of manual workflows and outdated operational practices.

And for companies that want to stay ahead? Embracing digital tools isn’t just smart. It’s essential. So, keep reading this blog till the end to know the amazing transformation of this industry.

How Do Oil and Gas Software Solutions Improve Operational Efficiency?

Running oil and gas operations is not easy. A lot is going on: equipment to manage, people to coordinate, and safety to maintain. That’s where oil and gas software solutions make a real difference.

Let’s talk about how it helps companies work more smoothly and avoid costly delays.

- From Old Systems to Smarter Tools

Many companies used to rely on SCADA systems for monitoring. But those tools are now outdated.

Companies today include IT solutions for the oil and gas industry such as ERP and RPA. These are systems that tie together various departments and manage activities such as data entry, maintenance of inventories and scheduling.

As an example, it is possible to update the logs and inform the correct team automatically, based on detecting low pressure by a sensor in a pipeline. Thanks to the automation in the oil and gas industry, you can now deploy your inspection data to the existing streaming solution. - Stopping Problems Before They Start

Breakdowns slow everything down. But with the help of software, companies can spot early signs of trouble.

AI-powered maintenance tools keep an eye on temperature, pressure, and other key readings. If something seems off, the system raises a flag. That gives teams time to fix the issue before it causes damage. - Clearer View of Assets

With current asset management systems, it is an easy task to trace down equipment at various sites.

This is whether it is a valve in a refinery or a compressor in the field, the engineers are able to get the state of the equipment and history of services on a single dashboard. It aids in planning and making fast decisions. - Smarter Inspections with Drones and Robots

Climbing tanks or checking pipelines used to be risky work. Now, drones can fly over large areas to inspect them. Robots go into tight spaces or dangerous spots.

The software collects this inspection data and shows the results in real time so that teams can act fast. - Working from Anywhere

Field teams can now use mobile apps to log updates, upload images, or receive instructions. Managers can see what’s happening without being on-site. - Making Better Use of Digital Twins

Digital twins are virtual versions of real assets. They help teams test solutions before making real changes, saving time and reducing errors.

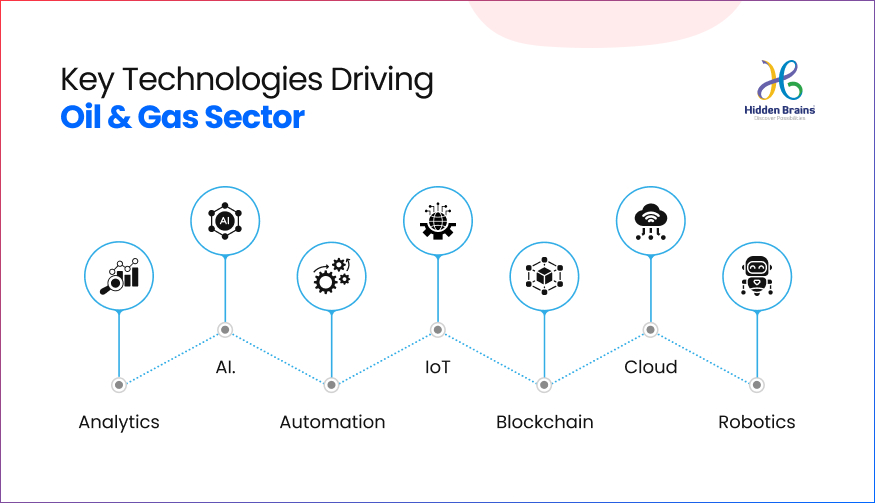

What Are the Key Ways Digital Tools Enhance Productivity in Oil & Gas?

Productivity used to mean more people and more equipment. But not anymore.

It is now a matter of smart tools that will help to plan better, make quicker decisions, and minimize slowdowns.

That is the area where oil and gas software development services can have a tremendous influence on the O & G streaming industry.

Let’s look at how each one helps teams get more done with less stress.

- Automation: Getting the Routine Work Off Your Plate

Automation in the oil and gas industry enables you to avoid wasting time on routine efforts. Such processes as reporting, monitoring, and scheduling are now managed with the help of software.

As an example, should the pressure decrease in the pipeline, the system can be programmed to detect it and alert, as well as generate a work order, all without human intervention. - IoT: Real-time Info from the Field

IoT refers to the process of gathering information through intelligent sensors of equipment and locations.

These sensors monitor 24 hours a day, 7 days a week, pressure, temperature or vibrations. Thus, when any motor begins to overheat, the system is immediately aware.

No guesswork. No delays. You find out what’s happening as it happens. - Analytics: Making Sense of the Data

Oil and gas operations create a ton of data. Analytics tools help turn that data into answers. For example, if a well’s output drops suddenly, analytics can tell you why.

It might be equipment wear, supply issues, or something else. You don’t just see the problem, you understand it. - Cloud Services: Everyone Stays in Sync

Cloud platforms help teams work together, even from different locations. A field worker can upload a photo or log a note.

A supervisor can review it instantly back at the office. No waiting. No lost info. Everyone’s on the same page. - Robotics: Handling the Tough Jobs

Robots are taking over the dangerous or time-consuming jobs. They make inspections within pipelines, crawling into tanks, or even going underwater, so your team won’t have to.

It reduces the time of inspection and prevents people from falling into danger. - AI: Smarter Help When You Need It

AI tools are like an extra set of eyes on your operations. They notice patterns, predict problems, and recommend what to do next.

Say a pump or suction chamber has been using more power than usual, AI will spot it and alert the team before it fails. - Blockchain: Trust in Every Transaction

Blockchain builds a secure, unchangeable record of each step in a process. In oil and gas, it’s useful for supply chain tracking.

For instance, you can trace oil from the extraction site to delivery, with full transparency at every handoff. No gaps. No confusion. Only confidence.

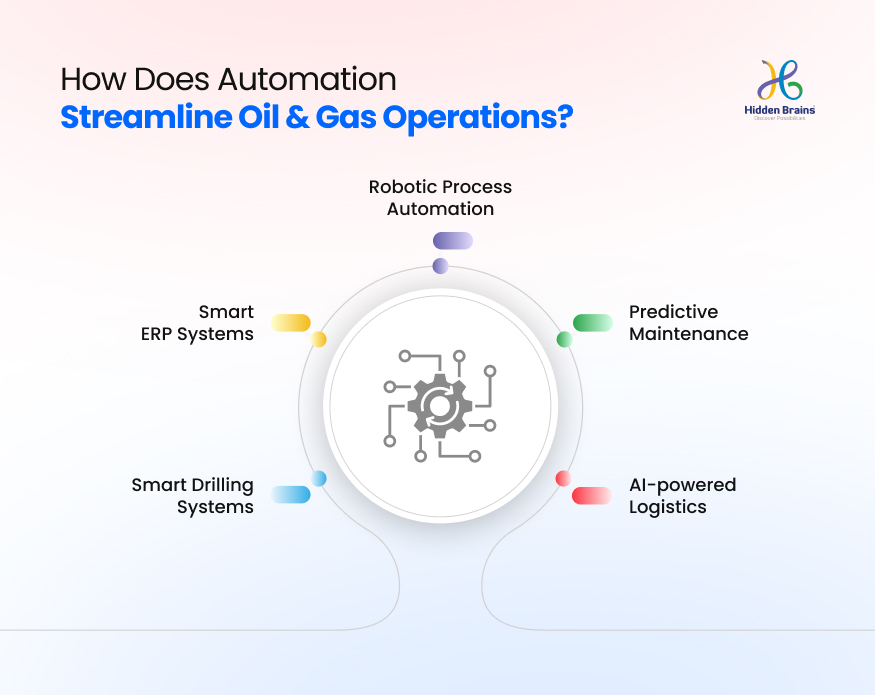

How Can Automation and Process Optimization Streamline Oil & Gas Workflows?

Do you know that more than 60% of oil and gas leaders anticipate the complete transformation of their operations with the help of digital and AI technologies by the year 2030?

It means Oil and gas software solutions powered by AI and other automation tools will entirely replace the manual process.

- RPA (Robotic Process Automation)

It takes over boring, repetitive tasks. Things like invoice checks, form updates, or vendor records. It’s fast and doesn’t miss a step. - ERP Systems

With everything on a single platform, inventory, finance, HR teams stay aligned and act faster. ROCKEYE ERP makes this possible, streamlining operations for Oil & Gas enterprises to cut costs and drive smarter decisions. - Smart Drilling Systems

Sensors collect data in real-time. Drilling speeds and angles adjust on their own. It saves time and reduces the risk of mistakes. - Predictive Maintenance

Instead of waiting for machines to break, alerts are sent in advance. Teams fix issues before they turn into big problems. - AI in Logistics

AI maps the best delivery routes and manages equipment movement. It cuts down delays and saves costs.

All this translates to shorter waiting, fewer mistakes and quicker decisions. Teams do not spend too much time correcting issues, but rather, they advance.

How Does Real-time Data Visibility Transform Decision-Making in Oil & Gas Enterprises?

Have you even heard of one of the biggest game-changers in the oil and gas industry nowadays?

Real-time data.

Whether on rigs or in refineries, teams already have a live view of performance, safety and production measures right in their hands. There will no longer be the necessity to wait to retrieve the daily or weekly reports. Lets see how it works:

- Online sensors and IoT devices continuously check the condition of equipment, the degree of pressure, and fuel consumption.

- Mobile applications and dashboard present that raw data in the form of comprehensible and actionable information.

- Managers have an opportunity to identify problems beforehand, redistribute resources faster, and react rapidly to any uncertain occurrences.

- In a co-operative endeavour, such as working on an offshore rig where there are potentially costly errors, or even disasters, such visibility may help avoid them.

It is not only the speed of decisions, but the quality of these decisions with support of live and correct information. And when every second counts, that is a big advantage in the industry.

How Does Predictive Maintenance Reduce Downtime and Maintenance Costs?

Think about this; what if your machines could tell you when they’re about to break?

That’s exactly what predictive maintenance does. Oil and gas IT services use AI and real-time sensor data to spot unusual patterns before they turn into problems. No more waiting for something to fail or spending blindly on routine checkups.

Maintenance teams get alerts in advance. Parts get replaced only when needed. And guess what? Less downtime, fewer breakdowns, and big savings on repairs.

In the case of oil and gas operations, this translates to up-time, fewer workflow hitches, and an overall upsurge in efficiency, devoid of guess-work.

In What Ways Do AI and Machine Learning Drive Innovation in Oil & Gas?

Imagine having a digital brain that learns from every drill, sensor, and pump. it’s already here, thanks to the expertise of custom software development services.

AI and machine learning are helping oil and gas software solutions to go from reactive to proactive. They crunch thousands of data points in real time to predict when a machine might fail or how a reservoir will behave. No more guesswork.

These tools also help optimize drilling paths, reduce fuel waste, and even automate routine decisions in control rooms.

It’s not about replacing people, it’s about giving teams better tools to solve complex problems, faster. And as the industry gets leaner and more digital, AI is proving to be the secret weapon behind better margins and fewer surprises.

How Do Cloud Platforms Enable Better Scalability and Remote Operations?

Did you notice how the industry’s moving away from bulky on-prem systems? Cloud platforms are leading that shift; whether it’s public, private, or hybrid.

Teams can access data and systems remotely securely anywhere; this works as a game-changer in remote locations and field camera crews. Teamwork becomes simpler, quicker, and effective.

Cloud tools can be scaled easily as well. The system scales with you, whether you are performing operations of 10 assets or 10,000, there is no large infrastructure expenditure. Asset tracking to real time dashboards all works more easily, more intelligently and a whole lot more connected.

Ready to Build Smarter Oil & Gas Solutions? Trust Hidden Brains

Hidden Brains brings 22+ years of tech expertise to the energy sector, helping oil & gas enterprises go digital with powerful custom software. From asset management to predictive analytics, our solutions are built to boost performance, cut downtime, and drive results. Whether it’s cloud, mobile, or AI, we tailor it to your goals.

Frequently Asked Questions

Got questions about how software is transforming the oil and gas sector? We got you covered!

What are the applications of oil and gas software solutions?

They help manage everything from exploration and drilling to production, asset tracking, compliance, and reporting. It’s like having a digital assistant keeping all operations in sync.

What are the key features of IT solutions for the oil and gas industry?

Look for features like real-time monitoring, predictive maintenance, mobile access, automated workflows, analytics dashboards, and strong integration with your existing systems.

Why does the oil and gas industry need custom software solutions?

Because every business runs differently. A tailored solution fits your specific needs, processes, and goals, giving you more control and better results compared to one-size-fits-all tools.

How does predictive maintenance reduce unplanned downtime?

By using data from sensors and equipment, the system flags issues early so you can fix things before they fail. This keeps production running smoothly and avoids costly repairs.

What role does cloud technology play in oil and gas?

It enables secure remote access, seamless data sharing, and scalable infrastructure, perfect for teams working across multiple sites or in the field.

Conclusion

The oil & gas industry is evolving and those who embrace digital transformation are leading the way. From AI to automation, the oil and gas software solutions are here to reshape operations. The time has come to be innovative, efficient, and increase. Are you ready to make the jump? The future of energy begins with more intelligent software.

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg)

![Sales & Distribution [Oil & Gas] Sales & Distribution [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/sales_and_distribution-icon.74d08193.svg?1.0.0)

![Fluid Terminal Management [Oil & Gas] Fluid Terminal Management [Oil & Gas]](https://www.hiddenbrains.com/blog/wp-content/themes/blankslate/assets/images/fluid_terminal_management-icon.4b3a27a4.svg?1.0.0)