- 75%

Reduction in Manual Design

Efforts - 65%

Faster Order

Completion - 50%

Boost in Operational

Efficiency

Achieving Unparalleled Efficiency and Precision in the Sheet Metal Industry.

Assessing Client’sBusiness Need

Crafting SuccessThrough Collaboration

Addressing inefficiencies like offline processes and complex operations, such as bending and hardware insertion, with precision and ease.

Delivering a scalable platform with advanced customization tools and real-time visualizations.

Frequent collaboration ensured alignment with industry standards and client expectations.

Revolutionizing User

Experience withReal-Time

Visualization

Efficiency Meets InnovationEmpowering Manufacturing

The Craft Cut Create platform was envisioned to transform the manufacturing process, addressing inefficiencies and empowering businesses with a streamlined, digital-first approach.

By automating labor-intensive processes, the project aimed to elevate productivity and precision, fostering industry-wide modernization.

Transition the traditionally manual workflows of sheet metal cutting and other manufacturing processes to a unified digital platform.

Simplify design uploads, material selection, service customization, and order placements.

Enable accurate processing of diverse file formats (.ai, .dwg, .dxf, .eps, .stp).

Reflect real-time 2D/3D visualizations of complex customizations like bending, hardware insertion, and finishing services.

Reduce manual efforts by 80% and accelerate order fulfillment timelines by 65% through automated workflows.

Ensure the platform is scalable to support bulk orders, increasing user demands, and expansion to related industries such as automotive, construction, and aerospace.

Deliver a platform with intuitive navigation, ensuring seamless adoption for both experienced professionals and newcomers in the manufacturing domain.

Provide users with quick, accurate quotes while minimizing operational costs for businesses.

Automate complex calculations like cutting lengths and material requirements.

Incorporate eco-friendly practices by optimizing material usage, minimizing waste, and promoting digital workflows that reduce reliance on paper-based operations.

This approach supports environmentally responsible manufacturing while aligning with global sustainability goals and cost efficiency.

TechnicalChallenges

Converting and processing diverse file formats (.ai, .dwg, .dxf, .eps, .stp) to extract precise design details and render accurate 2D/3D visualizations.

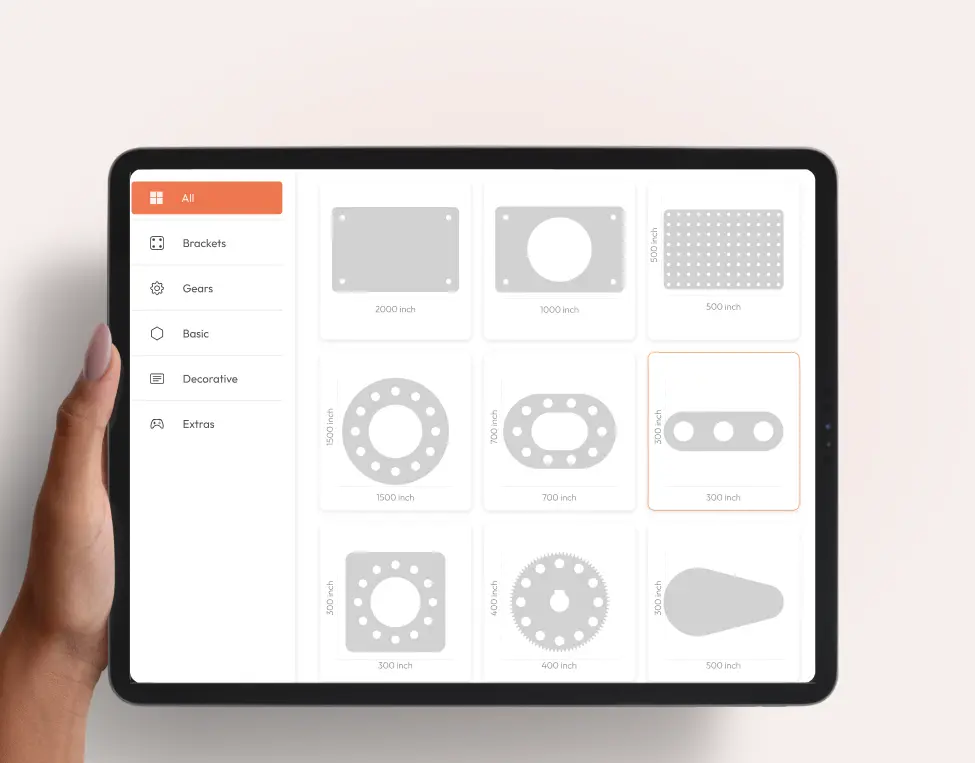

Developing an SVG-based library to support real-time resizing, customization, and updating of parts for consistent accuracy.

Implementing rules to handle material-specific constraints, such as bending angles, thickness limitations, and finishing requirements.

Enabling dynamic and precise real-time visualization of services such as bending, hardware insertion, and finishing to enhance user decision-making.

Automating accurate placement of hardware components, such as studs and standoffs, with real-time visualization in 3D previews.

Ensuring designs comply with CNC and laser cutting standards for operational precision and manufacturability.

Creating output files with all selected services (hole operations, bending, finishing) applied, ensuring compatibility with widely-used software like AutoCAD.

Designing scalable backend infrastructure to handle multiple concurrent file uploads and 3D operations without compromising performance.

Combining the robust backend capabilities of Magento with the dynamic and user-friendly front-end experience of React.

Maintaining smooth and responsive performance for real-time rendering and customization of complex designs.

Implementing intelligent checks to identify design flaws, tolerance conflicts, and manufacturability issues during file processing to ensure production-ready outputs.

Building an adaptive pricing engine capable of calculating real-time costs based on material type, service selections, and design complexity while maintaining high computational efficiency.

BusinessChallenges

Gaining deep insights into manufacturing processes, including drawing standards, cost modeling, and material constraints, to align with industry norms.

Meeting client expectations for accurate bending operations, dimension-specific designs, and error-free final outputs.

Defining a detailed library of over 50 materials with associated customization options and constraints to meet diverse user needs.

Delivering a platform that can handle intricate services such as laser cutting, bending, and finishing without errors or misalignment.

Developing a scalable system to manage growing user demands and large-scale bulk orders while maintaining efficiency and reliability.

Coordinating effectively across design, development, and testing teams to streamline workflows and ensure timely project delivery.

Balancing rigorous R&D efforts with tight deadlines to deliver a fully functional platform.

Meeting client expectations for accurate bending operations, dimension-specific designs, and error-free final outputs.

Leveraging cloud technologies like AWS EC2, S3, and RDS to optimize performance without inflating operational costs.

Incorporating cutting-edge manufacturing trends to ensure the platform remains relevant and competitive in the long term.

Hidden Brains’ Approach toCrafting Excellence

Hidden Brains took a systematic, collaborative, and innovative approach to deliver a solution that met

the complex demands of the manufacturing industry. Here are the key steps involved

Top PlatformFeatures

Supports multiple formats (.ai, .dwg, .dxf, .eps, .stp) with instant 2D/3D previews for real-time design adjustments.

Modify part size, dimensions, and attributes with real-time visual feedback ensuring precise specifications.

Choose from 50+ materials and services (bending, hardware insertion, finishing) with interactive previews.

Simulates 3D bending operations to visualize deformation and prevent design errors.

Hidden BrainsKey Additions

Hidden Brains revolutionized the sheet metal cutting industry by introducing advanced automation, real-time customization, and precision-driven innovations. The platform enables faster workflows, seamless integration of complex services like bending and drilling, and empowers businesses to scale efficiently, ensuring leadership in manufacturer industries.

Hidden Brains developed a fully customizable workflow automation system that adapts to different business processes within the sheet metal cutting and manufacturing industries, ensuring businesses can align the platform with their specific operational needs.

Designed specialized algorithms for seamless and accurate conversion of complex files from multiple formats (AI, DWG, DXF, EPS, STP) to fully interactive 3D models, allowing for precise design visualization and reducing potential design errors during manufacturing.

Introduced an intelligent material selection tool that automatically recommends optimal materials based on the user’s design and requirements, factoring in material properties, cost-effectiveness, and production feasibility.

Integrated advanced real-time reflection of all customization services (e.g., bending, cutting, hardware insertion) in the 3D visualization, ensuring that users see immediate feedback and adjustments as they apply services, improving accuracy and user satisfaction.

Implemented a comprehensive tracking system that streamlines order management, monitors production stages in real time, and ensures seamless coordination between teams, resulting in improved operational clarity and timely delivery across manufacturing workflows.

Designed a cloud-based infrastructure that not only provided scalability for increasing user demand but also ensured fast performance, real-time data synchronization, and robust security for sensitive manufacturing data.

KeyResults

Hidden Brains grasped the intricacies of the process, implementing a solution in carefully structured layers that ultimately evolved into a transformative offering, driving tangible value and positively influencing workflows.

By automating key aspects of the design and order process, Hidden Brains has reduced manual intervention by up to 80%, enabling businesses to focus more on strategic tasks rather than repetitive processes.

The streamlined automation workflow has reduced order processing time by 65%, accelerating turnaround times for both custom and bulk orders, leading to faster deliveries and improved customer satisfaction.

The intelligent algorithms for file conversion and real-time service reflections have significantly enhanced the accuracy of designs, ensuring that parts meet the required specifications and eliminating costly errors during manufacturing.

The integration of advanced workflow automation and intelligent material selection has resulted in optimized resource allocation and improved production efficiency, allowing businesses to handle larger order volumes without compromising quality.

With real-time 3D visualizations and tailored customization options, customers have been able to experience a smoother, more intuitive interaction with the platform, leading to better user engagement and higher retention rates.

Hidden Brains’ cloud-based infrastructure has provided businesses with the ability to scale their operations effortlessly, supporting increasing user demands and ensuring smooth performance even under heavy workloads.

The combination of automation, accurate cost estimation, and optimized workflows has helped clients reduce operational costs and increase profit margins, making the manufacturing process more cost-effective.

Regular communication, collaborative efforts, and integration with existing tools have fostered stronger collaboration between businesses and their teams, ensuring alignment on objectives and improving overall efficiency.

Traditional Manufacturing Vs.Craft Cut Create Digital Automation in Manufacturing

- Process Efficiency

- Workflow Integration

- Customization Flexibility

- Real-Time Feedback and Visibility

- Operational Costs

- Scalability and Flexibility

- Quality Control

- Time to Market

- Environmental Sustainability

Time-consuming manual processes with high chances of human error.

Disconnected tools and systems that lead to inefficiencies and delays.

Limited customization, requiring long lead times and prone to inaccuracies.

Limited or no visibility into production, causing delays and errors.

Higher costs due to inefficiencies, manual labor, and rework.

Scaling requires significant investments and may be slow.

Manual inspections lead to inconsistency and defects in production.

Longer production cycles with slow adaptation to changes.

Wasteful processes and higher material consumption.

Automated workflows reduce manual effort by 80% and speed up order completion by 65%.

Seamless integration of design, material selection, and order processing for smoother operations.

Real-time, flexible customization with immediate 3D feedback, allowing precise design modifications.

Real-time service reflection and visual feedback directly in 3D models, ensuring adjustments.

Automation reduces overhead costs, ensuring greater operational efficiency.

Cloud-based system easily scales to meet growing demand, providing operational flexibility.

Automated quality checks and error detection ensure consistency and high standards.

Faster prototyping and customization lead to a significantly reduced time-to-market.

Optimized material selection and resource-efficient processes reduce waste and energy consumption.

Other IndustryUse Cases

Automotive Industry

- Customization & Precision

Enables high-precision part design and real-time 3D visualization for automotive components like frames and brackets.

- Faster Prototyping

Streamlines prototyping with quick design modifications for custom vehicle parts.

Aerospace Manufacturing

- Complex Part Fabrication

Supports the fabrication of precise aerospace parts, including brackets and structural components.

- Optimized Material Selection

Recommends materials based on strength, durability, and weight for aerospace-grade designs.

Consumer Electronics

- Complex Part Fabrication

Designs custom furniture parts with precision in dimensions and finishes.

- Rapid Prototyping

Speeds up prototyping for new furniture designs, ensuring accuracy in components.

Furniture & Interior Design

- Customized Components

Designs custom furniture parts with precision in dimensions and finishes.

- Rapid Prototyping

Speeds up prototyping for new furniture designs, ensuring accuracy in components.

Industrial Equipment Manufacturing

- Tooling & Parts

Simplifies the design and manufacturing of complex parts for robotics and machinery.

- Bespoke Solutions

Creates custom parts for specialized industrial equipment with tight tolerances.

Architecture & Construction

- Custom Building Components

Designs HVAC ducts, steel frameworks, and panels with real-time feedback.

- Optimized Production

Reduces waste and improves efficiency in building material production.

Jewelry design

- Detailed Custom Designs

Creates intricate jewelry pieces with precise engravings and finishes.

- Rapid Customization

Prototypes and customizes jewelry with quick design changes and material options.

Who Can Benefitfrom This Solution

The Craft Cut Create platform caters to various segments within the manufacturing industry, including but not limited to

Manufacturers

Engineers

Enterprises (SMEs)

& Operations Teams

(B2B or B2C)

TechnologyStacks

Frontend

- Magento 2.4.6

(Website content & eCommerce modules)

- ReactJS

(Part Builder & Custom file integration)

- HTML, CSS

(UI design and responsiveness)

Backend

- Magento 2.4.6

(Website CMS & Ordering)

- Node.js

(Operations related to ReactJS)

- Python

(File reading & conversions)

AWS Services

- EC2

(Linux & Windows) for computing resources

- S3

Storage for file storage

- RDS

for Database Management

Other Tools

- Three.js

(3D visualization)

- Maker JS

(Geometric Modeling)

- Adobe Illustrator

(File Processing)

![[object Object] Insights](https://cdn-server.hiddenbrains.com/OurWork/_next/static/media/insights-companyThumb.4d0b5800.svg?1.0.0)